In a busy shop, tattoo machine problems rarely show up as a clean “broken or not broken” moment. More often, something feels slightly off: output drifts late in the day, the machine hesitates under load, or control becomes less predictable than it used to be. In daily studio use, these issues are less about quick fixes and more about what your workflow is telling you—about power stability, mechanical feedback, heat behavior, and how well the system holds together under repetition.

The goal here is not repairs. It is to help you read common tattoo machine problems as signals, so you can reduce workflow disruption and make better machine selection decisions over time.

Power and Output Consistency Issues

Power consistency is the foundation for output stability. When a machine behaves differently across similar setups, you lose time recalibrating your hand and your expectations—especially in professional tattoo studios where the same standards must repeat.

Sudden power drops during sessions

Power drops usually reflect a change in voltage stability under load. Load shifts with different cartridge groupings, longer continuous passes, and the cumulative demand of a long session. The key issue is not peak capability. It is whether the machine maintains a predictable response when conditions are no longer ideal.

Some tattoo stencil machine problems reported in studios follow the same pattern. The stencil can look fine at first, but unstable power delivery changes rhythm and pressure during early passes, so the transferred design breaks down sooner than expected.

Inconsistent output between similar setups

Inconsistent output is disruptive because it pushes you into compensation. You keep the same voltage setting, use a similar cartridge, yet the response feels different. When repeatability slips, you unconsciously alter pace, pressure, or angle. Over time, that compensation becomes “your technique,” even though it started as a system mismatch.

Vibration, Noise, and Mechanical Feedback Changes

Vibration and sound are not cosmetic. They are feedback channels. When they change, they often change before performance drops become obvious.

Increased vibration and its effect on control

Tattoo machine vibration affects control in small, cumulative ways. Increased vibration can show up as rougher edges in lines, reduced confidence in curves, and faster fatigue—then fatigue creates consistency drift later in the session. A stable system should feel steady across time, not only across strokes.

Unusual sounds as early warning signs

Unusual noise—new buzzing, a sharper whine, intermittent clicking—often signals a change in mechanical feedback or power delivery behavior. Even if the machine “still works,” sound shifts can indicate it is no longer operating in its normal band, which raises the likelihood of workflow disruption.

Starting, Stalling, and Intermittent Operation

Starting and stalling issues often get labeled as “random.” In reality, intermittent performance becomes visible when the machine is pushed into real working conditions.

Machines that hesitate at startup

Startup hesitation suggests inconsistent system response. In a professional setting, you rely on predictable starts, especially when switching tasks. Hesitation can mean the system is operating closer to tolerance limits than you want in production work.

Intermittent performance under load

A machine may run smoothly at first, then soften, surge, or feel uneven once the session settles into a steady rhythm. This pattern is tied to how the system delivers power during sustained demand—and how that demand interacts with heat buildup and mechanical resistance (and battery behavior in wireless units).

Heat Buildup and Performance Drift

Heat is normal. Uncontrolled heat behavior is where performance drift begins. In daily studio use, drift is costly because it is gradual and easy to miss.

How heat accumulation affects consistency

As heat buildup increases, operating behavior can shift. What matters is whether those shifts are small and predictable, or noticeable enough to change your pace and pressure. Weak thermal stability often feels like the machine “changes character” mid-session.

Performance drift over long sessions

Performance drift shows up when the first third of a session feels locked in, but the last third demands more attention to hold the same result. Drift often triggers more pauses, more corrections, and higher mental load.

Control Degradation During Extended Work

Control degradation is the point where you stop trusting the machine to respond the same way from one pass to the next.

Loss of predictable response

Predictable response lets you work smoothly without constant self-checking. When it fades, you spend attention managing the tool rather than executing the design. That trade-off usually shows up as slower work and more micro-corrections.

When compensation becomes part of technique

This is the studio trap: you adjust to protect the result, and those adjustments become habitual. If you are routinely compensating, treat that as a signal—your workflow is telling you something about stability, compatibility, or reliability.

Compatibility Issues Within the Workflow

Many studio issues are not caused by a single component. They come from interactions: cartridge, grip, machine, and power system combining in ways that amplify small inconsistencies.

Cartridge, grip, and machine interaction

Cartridge compatibility issues can present as unexpected resistance changes or output that varies between similar setups. Neither component has to be “bad” for the interaction to be unstable—especially when you switch configurations frequently and expect predictable behavior.

Power supply and system mismatch

System mismatch appears when power delivery and mechanical demand do not align. It can show up as intermittent performance, uneven response under load, or drift over long sessions. This is also where tattoo stencil machine problems are often misdiagnosed: the stencil gets blamed, but the root issue is a system that changes behavior under sustained demand, which accelerates stencil breakdown during early passes.

If wireless is part of your workflow, the decision is not simply wireless vs wired tattoo machines. The real question is whether the power system stays stable enough to protect repeatability.

Why These Problems Appear More Often in Daily Studio Use

A studio environment is a stress test. Even good tools show weak points when repetition is relentless.

Repetition exposes instability

Repeated use reveals patterns that do not show up in one-off sessions. A machine that is “fine most of the time” may still be the wrong choice for a workflow that depends on repeatability.

Professional environments surface issues faster

Professional workflows surface issues faster because the margin for variability is smaller. Studio owners often judge tools by how rarely they interrupt the day, not by how impressive they feel in a short test.

What These Problems Reveal About Machine Selection

The most productive way to think about tattoo machine problems is to treat them as decision signals.

Problems as selection signals, not maintenance tasks

Recurring patterns—power drops, vibration changes, drift, intermittent performance—show what your workflow will not tolerate. That is the same logic behind what makes a tattoo machine professional: repeatable behavior under real conditions.

Choosing machines that minimize workflow disruption

Minimizing workflow disruption means fewer surprise pauses, fewer reprints, and less fatigue-driven drift. If wireless flexibility matters, evaluate wireless tattoo machine stability as a system attribute—not a feature claim—before you commit.

In professional settings, options like an inkone tattoo machine platform are often judged through this lens: consistent output, controlled behavior under load, and reduced variability in daily studio use.

Conclusion

Common tattoo machine problems in daily studio use are rarely isolated. They are signals about power consistency, mechanical feedback, heat behavior, and workflow compatibility. Reading those signals helps you reduce workflow disruption and make smarter selection decisions—so the tool supports the work instead of interrupting it.

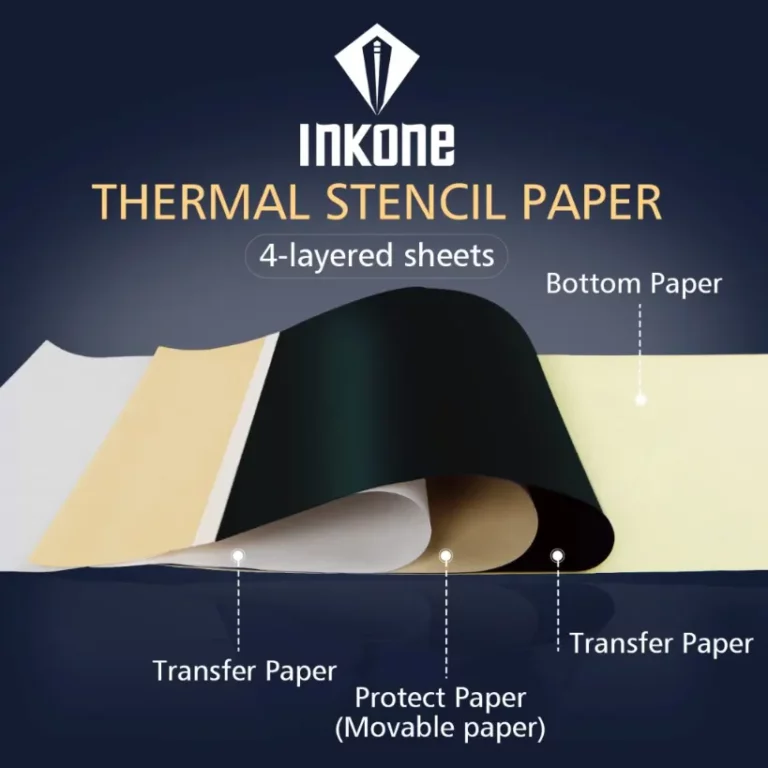

INKONE Tattoo Equipment: Engineering-Focused Solutions for Professional Studios

INKONE is a professional tattoo equipment supplier established in 2018, focused on tools that hold up under real working conditions. With in-house development across circuit schemes, machine structure, and integrated hardware and software, INKONE supports stable performance in daily studio workflows. The product range covers wireless tattoo machines, tattoo cartridge needles, tattoo power supplies, and disposable tattoo products, designed for professional channels where consistency and reliability matter.

FAQ

Q1: Why do tattoo machine problems appear more often in daily studio use?

Repetition exposes instability. Small shifts in power delivery, heat buildup, and mechanical feedback compound into drift and inconsistency.

Q2: What causes intermittent tattoo machine performance under load?

It often reflects system behavior under sustained demand—how power delivery, resistance, and heat interact once the session rhythm settles in.

Q3: How does tattoo machine vibration affect control?

Vibration increases fatigue and micro-instability, which can reduce line confidence and create consistency drift during long sessions.

Q4: Why do machines feel different even with the same settings?

Similar setups can produce different responses due to load changes, component interactions, or system mismatch that shifts behavior under real conditions.

Q5: How can studios reduce workflow disruption caused by tattoo machine problems?

Prioritize stability, predictable response, and workflow compatibility in machine selection, and judge tools by consistency across long sessions and repeated use.